Over the past few years I’ve been distilling down some of my ideas on the cutting theory of hook tools. Some of this comes from the work I am doing on my book on pole lathe turning for Lost Art Press…

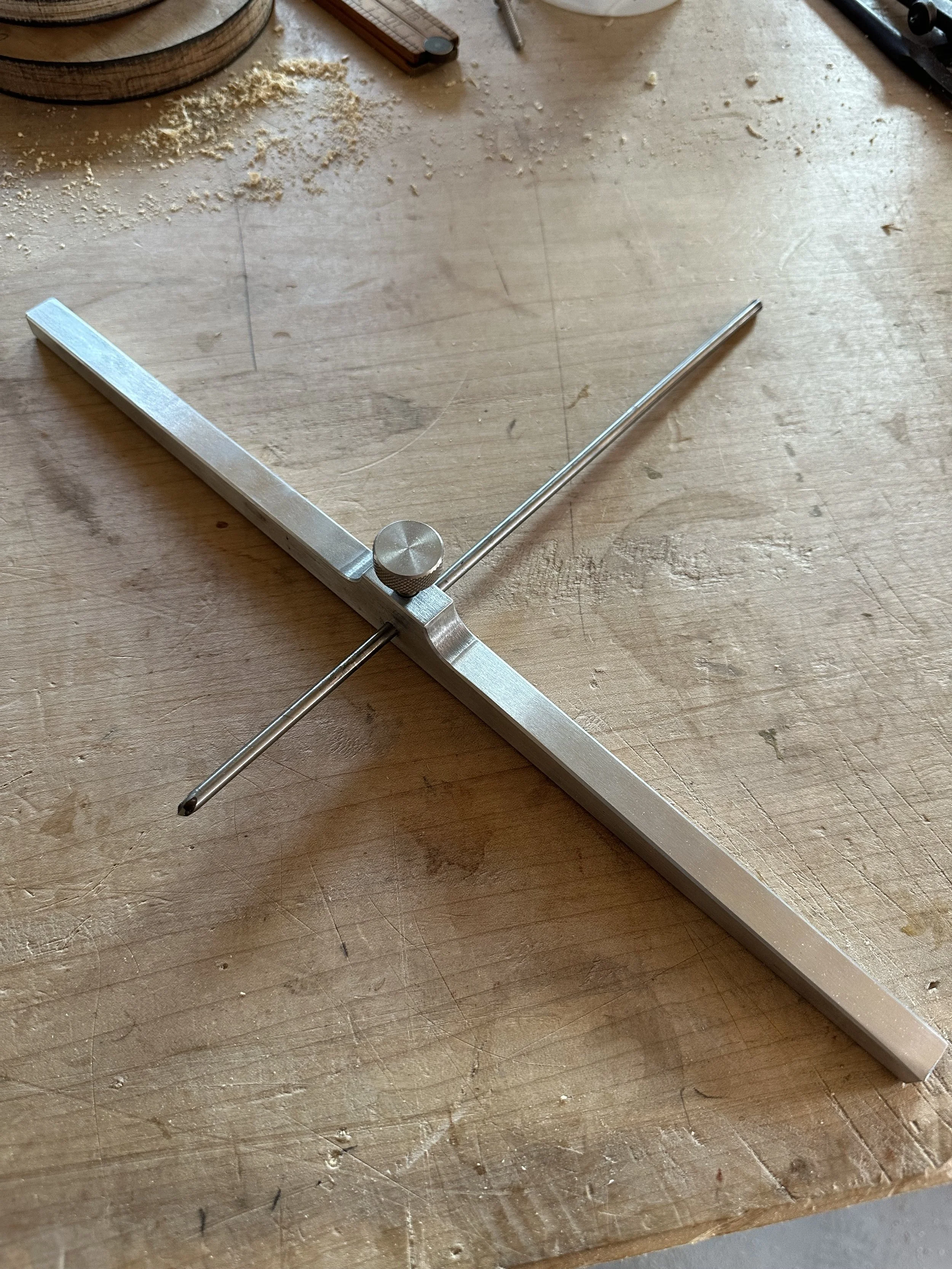

Read MoreI’ve been developing a tool to help wood turners….

Read MoreIn August 2023 we hosted a Japanese spoon carver named Kotaro Okubo at our craft school in Ashland, Wisconsin. Kotaro specializes in the use of the nankin kanna or wooden bodied spokeshave.

Read MoreThis summer we will host a class at our school with one of Japan’s best spoon carvers, Kotaro Okubo. If you are interested in Japanese woodworking, craft, or making ethos, this will be something you won’t want to miss. It will be great.

Read MoreThis past year has been unbelievable…really. We bought a small garage on a double lot, a few blocks away from our home. In that time we nearly rebuilt the existing structure and added a whole second story, built a fence, planted 100 basket willow cuttings, and garden with woven willow fence.

Read MoreWe have some exciting news to share. As part of Barn’s visit from the UK to the US this coming Spring, 2023 he’ll be teaching a workshop at Woodspirit School in Ashland, WI. Actually we’ll be teaching it together.

We’re calling it a Spoon Carving Masterclass and the class will happen March 31-April 2, 2023.

Barn and I are…

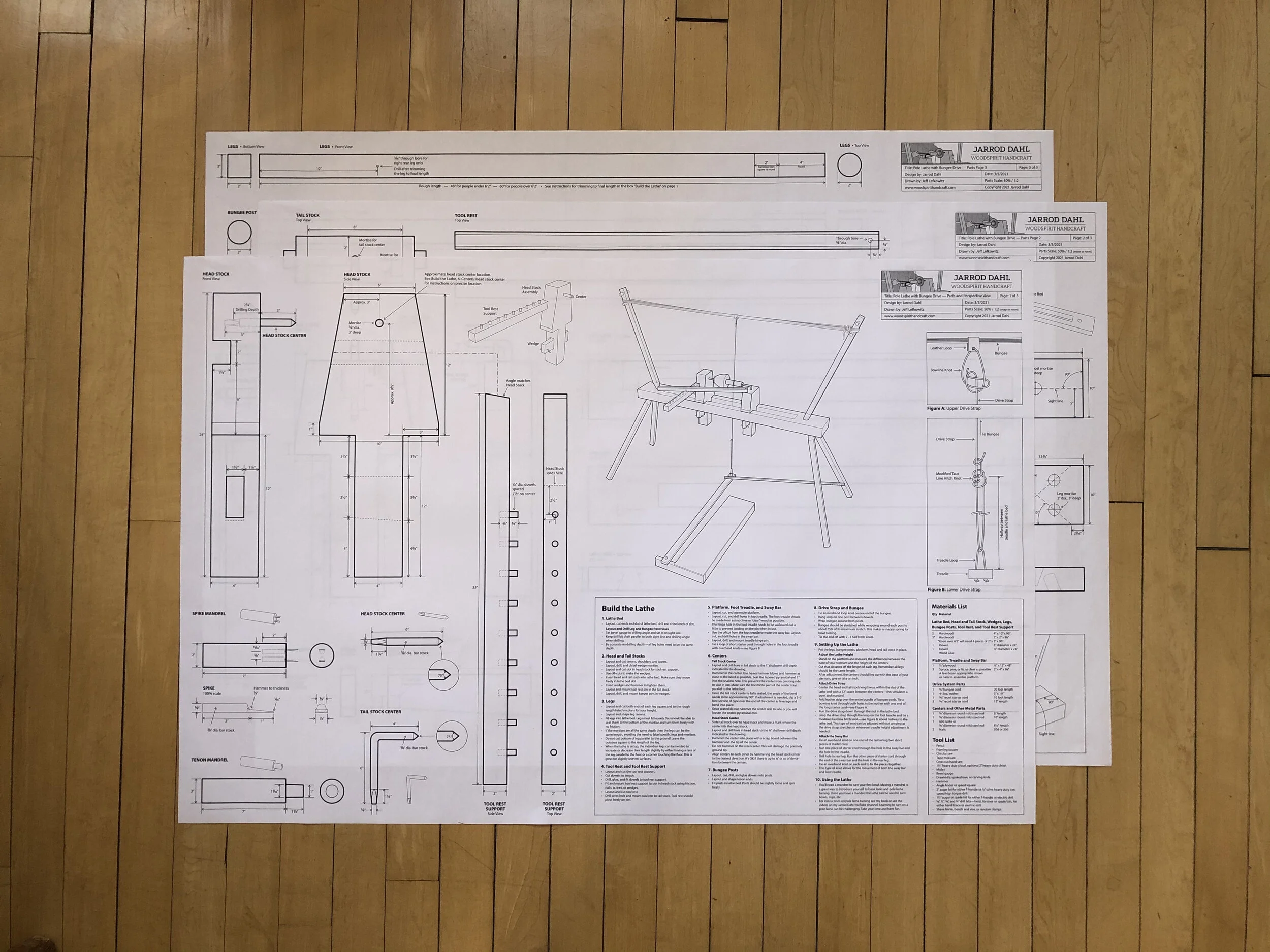

Read MoreThis past weekend I taught a pole lathe turning workshop to three students at our school here in Ashland, WI. The classroom space is small and I only have four lathes so from that point of view the class was nearly full. I’ve taught good turning classes with as many as twelve students, but there are benefits to small classes….

Read MoreLast November we bought a small building just a few blocks away from our house in Ashland WI. It was a bit spontaneous, but we knew it would mean something good. We’d been driving by the vacant building for years, often daydreaming about what we could do with it….

Read MoreWhile in Japan I learned of another finish known as liquid glass which was tasteless, odorless, and had a very matte finish. In fact, the wooden items I saw appeared not to have a finish at all, and yet still beaded water on its surface. I was obsessed. Back home I spent months searching for more information. If you search liquid glass on the internet, what comes up is either an epoxy or nano finish. But that’s not what the liquid glass I knew was.

Read MoreWooden tableware has a rich and long history within the Japanese culture. We share that history here in the West, but the widespread use of woodenware largely ended a few generations ago. There are some exceptions—one being the large diameter bowls produced en masse by bowl mills here in the States. But in Japan the timeline is unbroken and this is one of the reasons why I traveled there…

Read More